Note: these gear teeth had to be hand filed to remove the burrs caused by the splitting operation – all 468 teeth!

Mk II Update 8-27-2015

(click images for larger versions)

While some people have been laying on the beach, I have been working away in the shop.

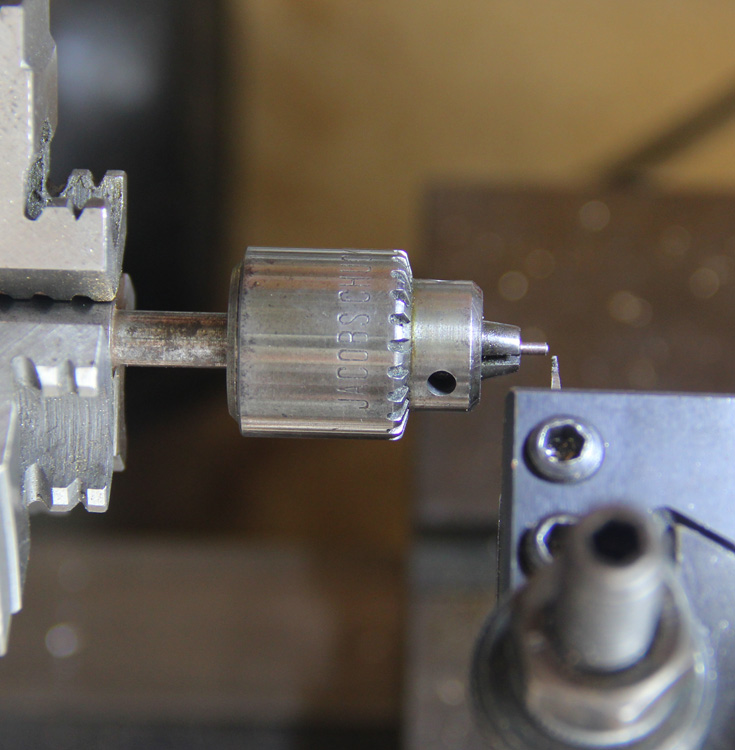

Spur Gear: I removed the temporary shaft that was used to split the gears

to required thickness.

Note: these gear teeth had to be hand filed to remove the burrs caused by the

splitting operation – all 468 teeth!

Then machined up a bushing to reduce the ID to the dimension required for the

rear axle. I used the same 303 stainless steel as the spur gear – with

a 0.0007” interference press fit for the gear and 0.0005 for the axle.

The finished assembly runs very true.

Following this, the pinion stock was bored & reamed to fit the motor shaft (1mm)

These were then cut to the 0.040/0.045” thick pieces (used a jeweler’s saw to minimize burrs).

The R/H rear wheels were machined up – same basic operation as the L/H wheels

The L/H wheels were remade – the axle holes were not sized for the drill-stock

axles. The bores were reamed to precise dimensions (had to buy more tools!).

Getting back to the motors – the OD of the armatures laminates were ground to 0.268/0.269” by Joel Pennington (he has some machine tools that, although I would really like to have, I cannot see enough use to justify the costs. Thanks Joel).

These were balanced using the old school razor blade setup. I elected to balance each using steel filled JB Weld – this method does not interfere with the anti-hysteresis coating on the laminates, which is designed to prevent heating and losses.

Time to start final assembly of the motors – Oh, did I mention that the Tyco/Mabuchi standard brushes didn’t fit into the Mk II brush tubes! These had to be turned down from 0.063” to 0.058”

Finally the motor/geartrains are ready for assembly.

Here they are – 13 running units! The gears need to be lapped in for perfect fit and the axles need to be cut to the final lengths and a “flat” milled for the L/H wheel set screws.

Now, onto the chassis final design and construction!

This will allow the tires to be fitted, after a final OD is determined and the

front wheels & tires machined up.